"Everyone in the room laughed”

In 1982, at the centenary dinner at the Maryborough Town Hall, Lambert Hyne, who had put his mind to evolving in the new economic conditions, predicted that within 30 years, homes would be made out of softwood pine, rather than using it only in certain parts of the home design.

Chris Hyne remembers the speech clearly, saying: “Everyone in the room laughed and shook their heads – it couldn’t be done”.

This visionary idea was inspired by the belief that house framing could now be wholly made of pine and Hyne began to move away from native hardwood for good, fulfilling Lambert’s perceptive prediction.

At this time, led by Warren Hyne, R.M.’s great grandson and a respected captain of industry, the business transformed from small scale sawmills to high volume modern softwood processing.

At the forefront of this transition was the development of a new high technology Tuan Mill, the company’s single biggest project.

Tuan Mill – a new era of softwood framing

In a hotel room in Sweden in the early 1980s, Warren and his brother Richard worked through the weekend to devise an idea on how they could afford the best sawmill equipment from German manufacturer Linck for the new Tuan Mill.

They settled on the unusual idea to build the mill ‘back to front’ – building the dry mill and kilns first, then the sawmill, as a way to afford the project.

Their efforts began to take shape in 1985 and included high temperature kilns and a high-speed planer with fully mechanised machine stress grading and handling in the dry mill. Operations began in 1986, with the green mill built later, in 1989, with an official completion and opening in 1990.

“It was the start of a revolution in the house framing story of Australia, because at that time most of the house framing was still hardwood,” says Chris Robertson, who joined the Tuan Mill as Project Manager the year the green mill was built. “They needed to convert customers in the market away from traditionally hardwood into this new more reliable structural product.”

Combining the best overseas technology with Australian innovation, Tuan Mill brought several “firsts” that established industry best practice and were good news to the timber industry and the housing market in particular.

These included revolutionary high temperature kiln drying techniques developed by Hyne in conjunction with the CSIRO, an enormous help with research and development for the timber industry, to make slash pine a stable and viable product for timber framing.

A pine sawmill is very largely designed around the kiln operation. If you don’t get the drying operation right, you will never get a good product, and Hyne got it right with the Tuan mill successful from the time it was built.

Hyne would grow from a medium-sized player in this market to one of Australia’s biggest exporters of softwood and the largest exporter of Australian-grown plantation softwood as well as a world leader in high temperature drying.

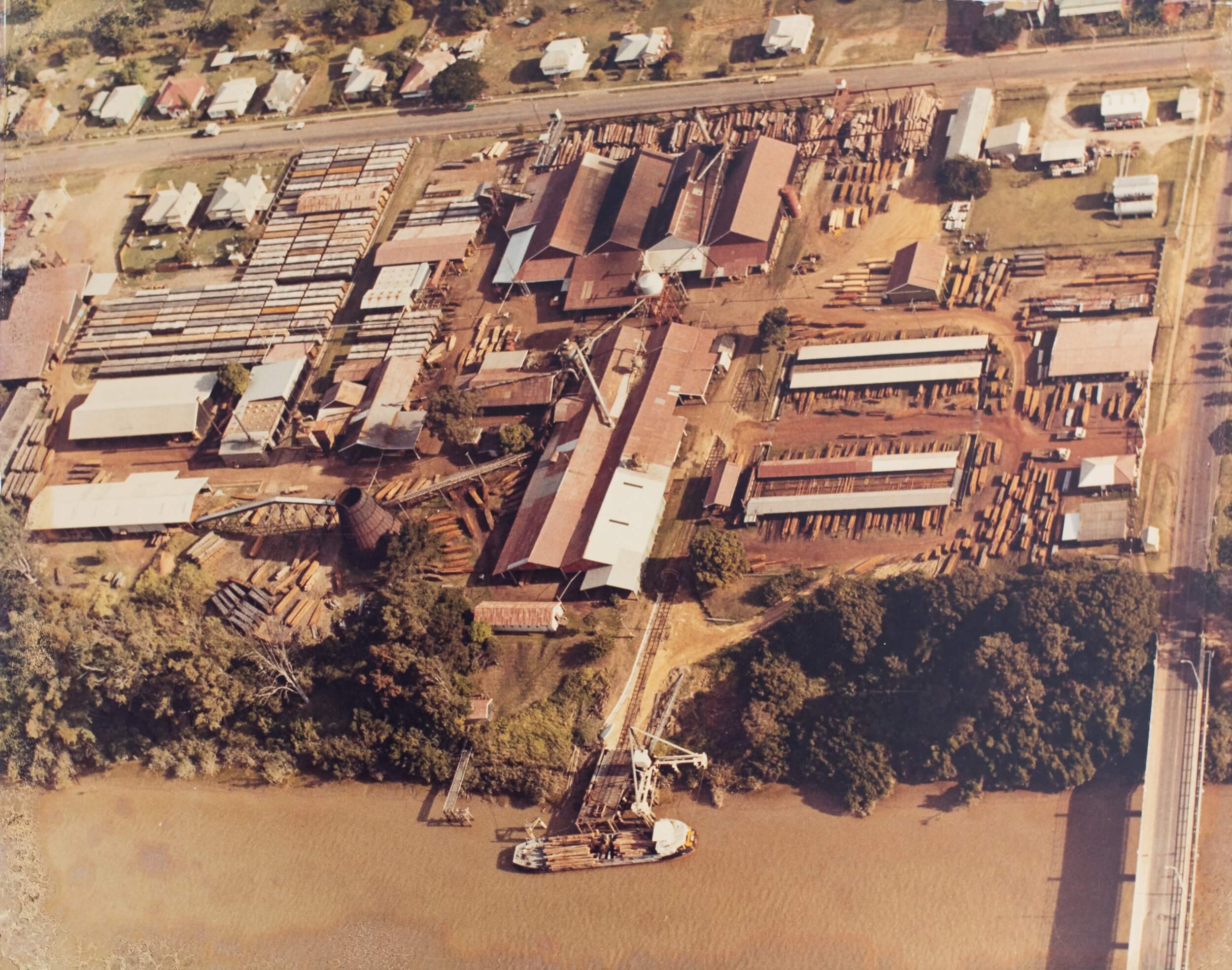

Distribution centres expand to include retail and trade hardware

In the 1980s, the softwood pine revolution had begun and, despite being early advocates and adopters of softwood, Hyne Timber still reflected the traditions of the timber industry as a predominantly hardwood business. In addition, the business operated a treatment plant at Melawondi, a hardwood transmission pole plant at Granville, as well as hardwood mills at Maryborough, Innisfail, Gladstone, Monto, Mundubbera, Dingo and Rockhampton, a cypress and hardwood mill at Chinchilla as well as joint ventures at Hervey Bay and Gayndah.

There were also three plantation pine plants at Melawondi, Pie Creek and Granville, as well as joint ventures at Gayndah, Biggenden, Baralaba and Bondoola, five gang-nail roof truss plants, four wall frame plants, a laminated beam factory at Maryborough and three pole preserve installations.

Retail outlets were also set up and selling direct to customers from Browns Plains and Zillmere in Brisbane to Maryborough, Hervey Bay, Gladstone, Rockhampton and Townsville.

The core business of Hyne had shifted in many directions.

“We were always in retail as a business – all our sawmills fed into distribution centres that carried a few nails and bits and bobs,” said Peter Hyne. “However, in the early 80s, we had pushed into the hardware industry more and expanded distribution centres to include retail and trade hardware.”

Initially, many were started as timber yards, some with frame and truss operations attached. There were also operations in New South Wales in Moruya and Merimbula, with several hundred people employed across all sites. But these operations broadened Hyne’s interests to a point that would one day need to be re-focused back to its core as new economic conditions loomed.

The nineties

“Getting out of trade and retail … after 100 years of selling to builders”

The nineties saw the selling off of the retail operations, which caused some disruption in small centres, where people were used to being able to buy what they needed from around the corner.

However, the move from retail to wholesale distribution (beginning in Rocklea, then the Gold Coast, Sydney, and a small outlet in Cairns) was welcomed by many customers who saw Hyne as a competitor, selling direct to their customers: the builders.

Alongside these changes, in 1995, ACI Pine Hoop operations was acquired, which consisted of a sawmill, dry mill, docking line and bandsaw operations located just outside Imbil, as well as a moulding plant in Brisbane, which was brought over to the headquarters in Virginia. There was also a treatment facility at Yandina.

This refocused Hyne’s core business and the selling off of surplus or non-performing assets, such as the sale of the Merimbula and Zillmere retail businesses, allowed for a new direction, which would see twelve warehouses opening, and the company becoming world leaders in high temperature drying.